Showing all 7 results

HF-120 Unscreened Cable

Hi-Flex 120 data cables are designed to last even in the most hostile chain or free movement applications. Abrasion is reduced to a minimum by using a Polyurethane low friction sheath. For maximum life Hi-Flex Data cables should not be exposed to torsional stresses or twisting. Many sizes now available with UL approval.

Image representative of product style, product supplied may vary.

- Low friction polyurethane sheath for abrasion resistance

- Fleece tapes and talcum to strengthen the core bundle

- Wide range of sizes

- For flexing applications

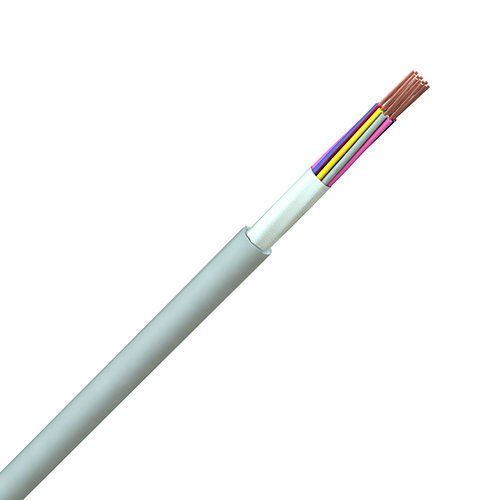

HF-120-C Screened Cable

Hi-Flex 120-C screened data cables are designed to last even in the most hostile chain or free movement applications. The HF-120-C copper braid screen protects the signal from EMI while the TPE insulation supports the highly flexible conductors. Abrasion is reduced to a minimum by using a polyurethane low friction sheath. For maximum life Hi-Flex Data cables should not be exposed to torsional stresses or twisting.

- Low friction polyurethane sheath for abrasion resistance

- Fleece tapes and talcum to strengthen the core bundle

- Tinned copper wire braid, protection from EMI

- Wide range of sizes

- For flexing applications

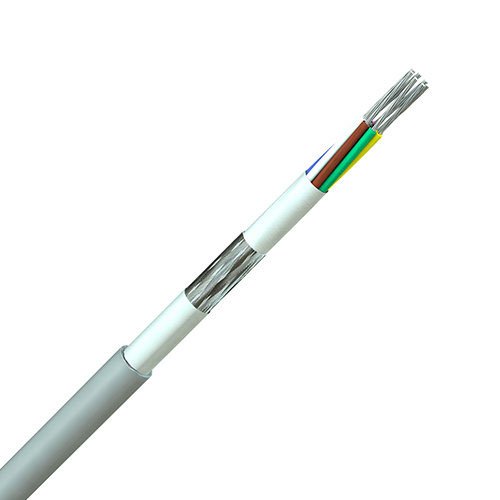

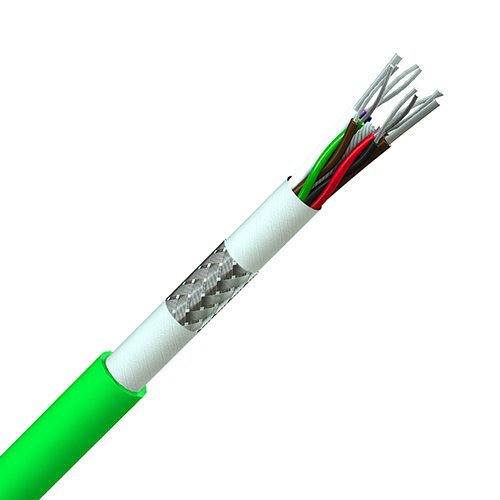

HF-120C-TP Paired Screened Cable

The Hi-Flex twisted pair data cable is ideally suited to mechanically challenging data transmission applications. The tough Polyurethane jacket is cut and abrasion resistant, while being unaffected by many solvents and oils. The tinned copper braid screen copes well with frequent flexing and at the same time maintains signal integrity by minimising the efforts of electromagnetic interference.

- Low friction polyurethane sheath for abrasion resistance

- Fleece tapes and talcum to strengthen the core bundle

- Tinned copper wire braid

- Wide range of sizes

- For flexing applications

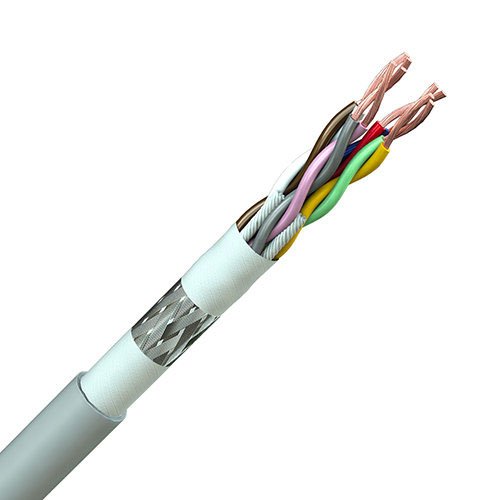

HF-265 PUR Encoder Cable

Used for precise data transmission, these cables meet the specific requirements of automation control gear manufacture. Fine copper wire strands with high performance insulation and sheathing materials make them ideal for regular flexing applications including use in cable chains where cut and abrasion resistance is vital.

- Low friction polyurethane sheath for abrasion resistance

- Fleece tapes and talcum to strengthen the core bundle

- Tinned copper wire braid

- Wide range of sizes

- For flexing applications

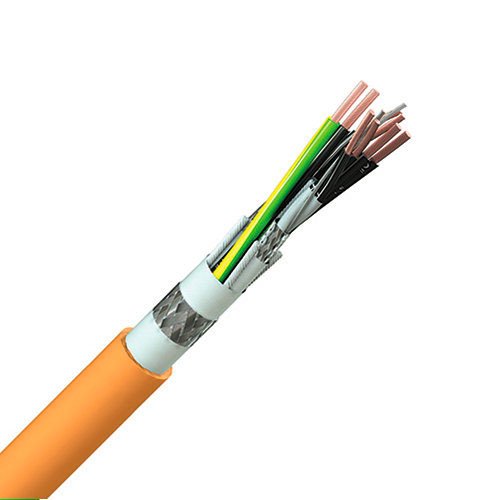

HF-275 PUR Servo & Feedback Cable

Cables combining control, signal and power cores are now commonly used in industrial automation. Fine copper wire strands with high performance insulation and sheathing material make them ideal for regular flexing applications. A wide variety of core combinations are manufactured as standard but please call us to discuss your specific needs. We are constantly increasing the standard range and will produce special designs for low minimum order quantities.

Image representative of product style, product supplied may vary.

- Low friction polyurethane sheath for abrasion resistance

- Fleece tapes and talcum to strengthen the core bundle

- High levels of screening

- Wide range of sizes

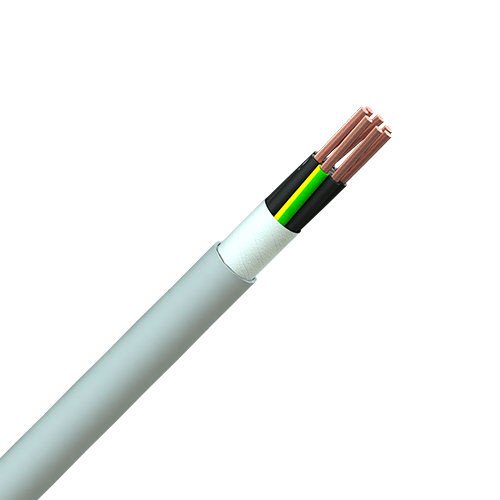

Hi-Flex HF-100 Unscreened Cable

Abrasion on cables that are constantly flexing is becoming a much more widespread problem. To overcome this, FS Cables have introduced the HF-100 range of polyurethane sheathed cables which will outlast conventional PVC sheathing.

- Low friction polyurethane sheath for abrasion resistance

- Fleece tapes and talcum to strengthen the core bundle

- Wide range of sizes

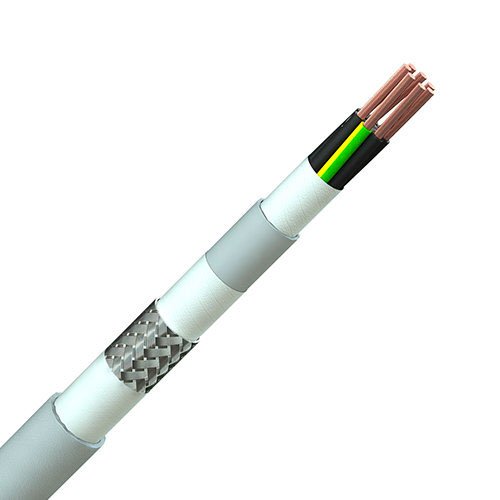

Hi-Flex HF-100C PUR Screened Cable

Abrasion on cables that are constantly flexing is becoming a much more widespread problem. To overcome this, FS Cables have introduced the HF-100 range of polyurethane sheathed cables which will outlast conventional PVC sheathing.

- Low friction polyurethane sheath for abrasion resistance

- Fleece tapes and talcum to strengthen the core bundle

- Tinned copper wire braid

- Wide range of sizes